Most Conventional & Popular Mill for Rolling up to 0.2mm Output Thickness from

Most Conventional & Popular Mill for Rolling up to 0.2mm Output Thickness from

Input strip thickness of 1.6 to 1.8mm (Provided all other features of Emulsion

parameters and Roll Force along with Rolls are within acceptable limits. With

increase in Emulsion Performance and Roll Chemistry, even thinner Strip Gauge

at output is possible.

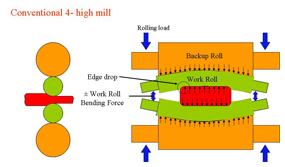

Basic setting facility for strip gauge control is an electro–mechanical screw down

or, in modernized plants, a hydraulic roll positioning system. In the case of

conventional four–high mills, work roll bending providing a way setting to influence

strip shape and flatness within limits is considered an improvement on the rigid roll contour, in conjunction with an on – line flatness measuring, a partial automation

is possible.

4- Hi Mill Specification

Special Mill Features

- Automatic Gauge Control (Close Loop AGC–Feed Forward/Feedback/Mass Flow)

- Positive and Negative Work Roll Bending

- Intermediate Roll Shifting

- Quick Work Roll with Hydraulic Side Shifter

- Hydraulic Back up Roll Change

- Overhung expand/collapse type Reel Mandrels with outboard bearing support.

- Constant mill pass line wedge adjust system

- Air oil Lubrication for Bearings (WR/IMR/BUR)

- Center Position Control for first Pass